Dx53D/SA1d High Quality Aluminized Steel Tube as 120g Application for Exhaust System/Exhaust Muffler Pipe

Basic Info

| Model NO. | SA1D AS120 |

| Usage | Hydraulic/Automobile Pipe, Muffler Tube of Exhaust Systems, Cylinder Tube |

| Section Shape | Round |

| Standard | ASTM A463/JIS G3314 |

| Delivery Time | Within 15 Days After Deposit |

| Application | for Automotive Parts |

| Product Name | Aluminized Steel Tube |

| Grade | Dx53D/SA1d |

| Aluminum Coating Value | 40/40G/M2 or 60/60G/M2 |

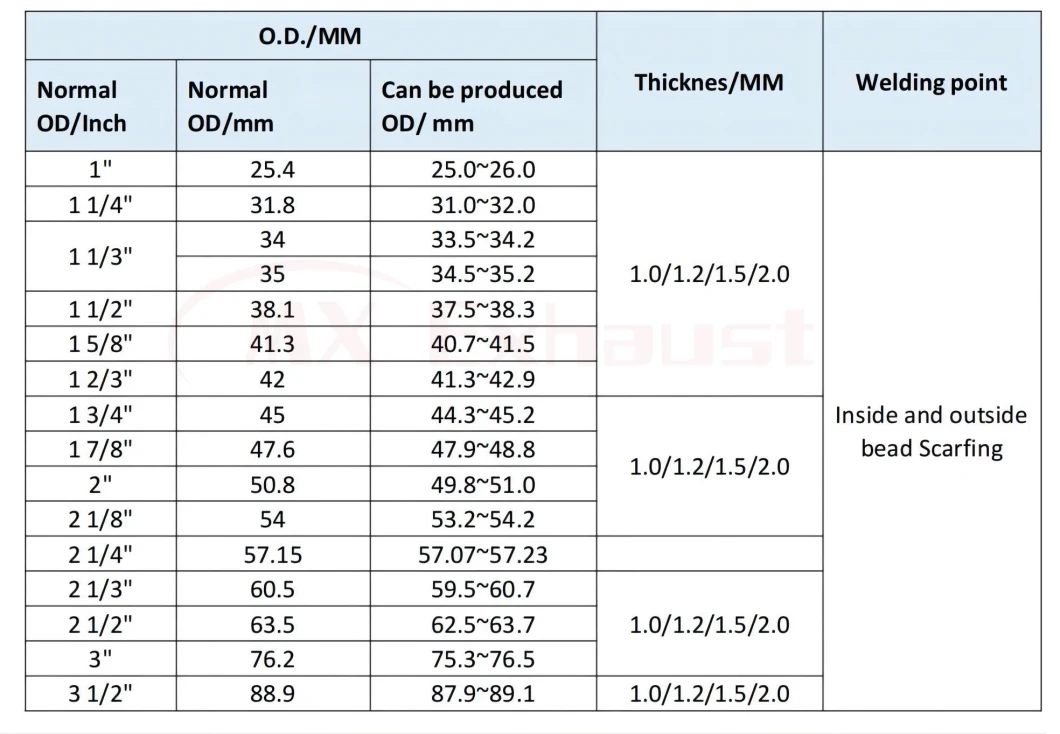

| Thickness | 0.8/1.0/1.2/1.4/1.5/1.6/2.0/2.3mm |

| Length | 1000-6000mm, or as Customized |

| Transport Package | in Bundles with PVC Bags or by Iron Case |

| Trademark | M. X or as customized, OEM Logo Accepted |

| Origin | China |

| HS Code | 7306309000 |

| Production Capacity | 50000mt/Year |

Product Description

Item Name: Aluminized Steel Tube with Aluminum Coating 80g/120gRaw Material: Superior Quality by POSCO or VAMA in ChinaQuality: DX53D/SA1DMade by High Frequency Welding Machine

Main Applicaton Scope:

Aluminized Steel Tube for Automotive application like as Muffler tube of Exhaust Systems, Cylinder tube of Shock absorber and Steering parts ect.

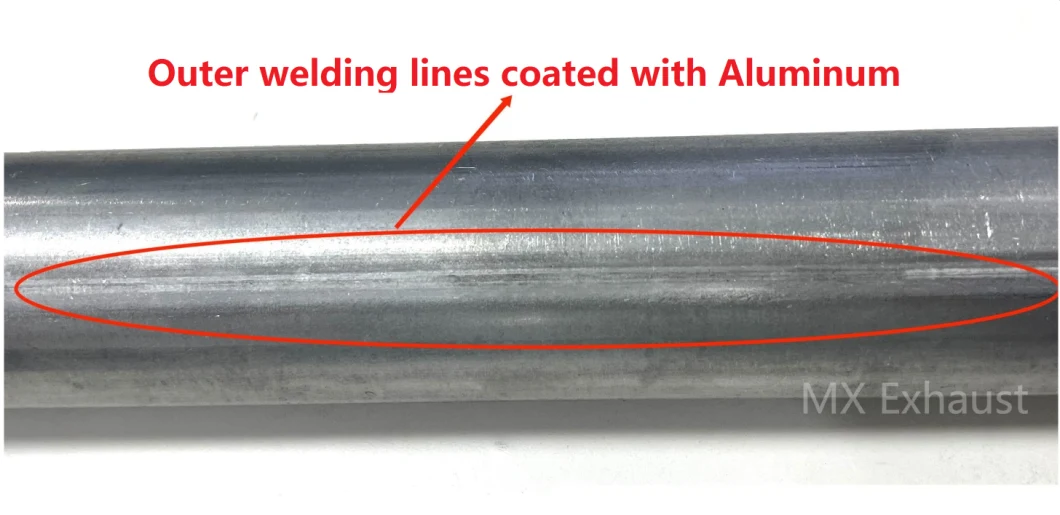

Our Product Features:1. Inside and Outside Bead Scarfing2. Outside Metallizing for Aluminum Coated Pipes3. Higher Expansion Rate4. Smooth Surface Roughness5. Accurate Roundness6. Superior Quality for Bending

Product Parameters

Application

Application Scope:

Packaging & Shipping

Our Advantages

WHY CHOOSE US? WHAT WE CAN DO?

We are the biggest Professional manufacturer in China for ERW Aluminized Steel Welded Pipe DX53D/SA1D, 80G/120Various Aluminized pipes and stainless steel welded pipes can be provided. If you need, pls do not hesitate let us know!!!We manages 26 pipe manufacturing lines, 43 units of bent pips lines, 18 automatic welding lines, 1 ERW(high frequency) pipe manufacturing line, 4 decorative tail pipe lines and other production lines, along with more than 800 diverse equipment and facilities.1). Founded in 2001 and experienced in the field of exhaust system and industrial pipe for 18 years.2). Management system certification: ISO9001, TSI169493). Sales network expends from over domestic sales to all over the world.

Prodcution Site

OUR MACHINE: High Frequency Welding Machine(HFW/ERW)

Under HFW Welding lines, our production capacity is 24mt/8 hours, the welding speed is 60meters/Miniute and the welding quality is stable. When production, Inside and Outside Bead Scarfing, Outside Metallizing for Aluminum Coated Pipes, and Eddy current tesing while production.

Abundant Raw material from POSCO or VAMA in China, High Technical Welding methords and the superior raw material enabling for the pipes welding points won't broken when end-user making bend tubes or spinning tube.

Our Team

We manufature products according to customer drawings, participate in drawing design in necessary. Upon establishment, our company has always been sticking"customer first" . All employees have been working conscientiously, managing to meet all the client demands by diligence and wisdom.

Our Service

1)Strict quality control during the process2)Competitive price3)OEM is acceptable4)Professional designed5)High performance full exhaust system customers design and logo are welcome6)One year warranty7)Delivery on time and best after-sales service

FAQ:

Q1. Can we make our logo on the product? Of course. Please send us your logo, provided that your logo is authorized Q2. Can you provide samples? Yes. Q3. Is it possible to provide OEM service?Yes, customers can customize the design and size of the product. We have a professional R & D department to cooperate with your design. Q4. What is the minimum order quantity? There is no minimum order quantity if the product is in stock.Pls consult our customer service staff, there will be a discount for you!!